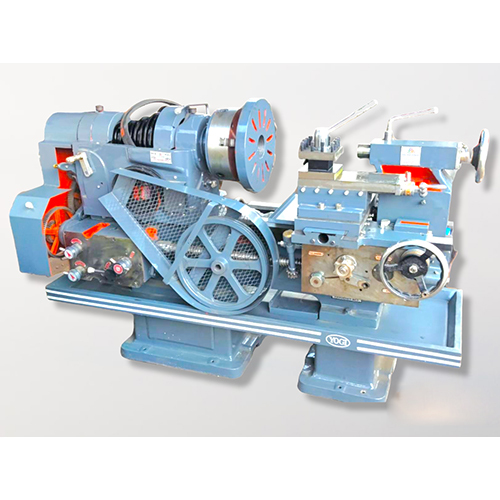

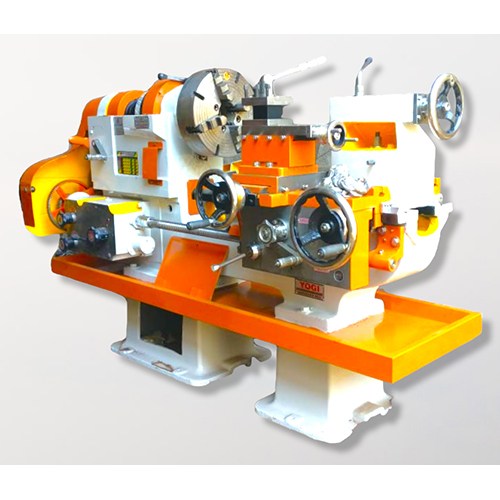

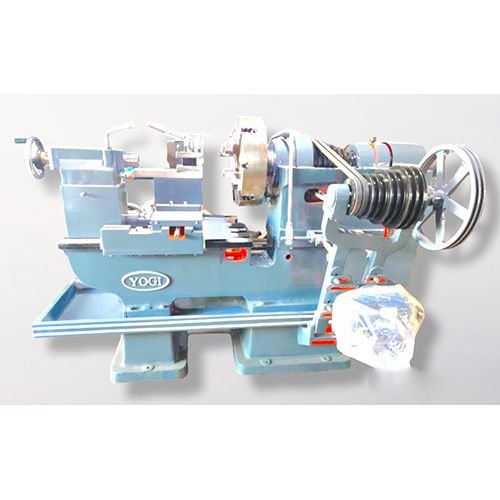

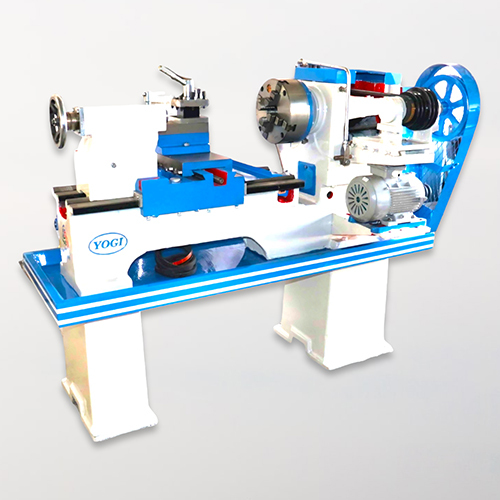

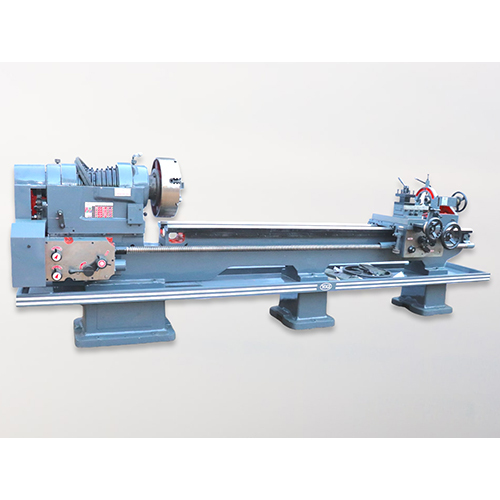

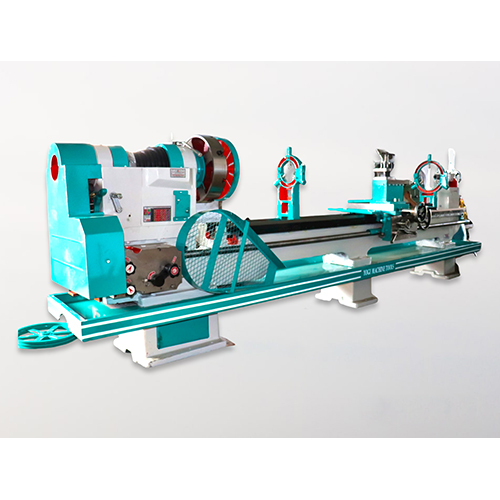

5.5 Feet Heavy Duty Lathe Machine

Product Details:

- Material Metal

- Automatic Grade Automatic

- Control System Human Machine Interface

- Feature Lower Energy Consumption

- Warranty Yes

- Click to View more

5.5 Feet Heavy Duty Lathe Machine Price And Quantity

- 215000 INR/Unit

- 1 Unit

5.5 Feet Heavy Duty Lathe Machine Product Specifications

- Automatic

- Lower Energy Consumption

- Metal

- Yes

- Human Machine Interface

5.5 Feet Heavy Duty Lathe Machine Trade Information

- Cash in Advance (CID)

- 10 Unit Per Month

- 30 Days

- All India

Product Description

A 5.5 Feet Heavy Duty Lathe Machine refers to a lathe machine with a bed length of 5.5 feet. The bed length represents the distance between the headstock and the tailstock and determines the maximum length of the workpiece that can be accommodated on the machine. This is designed for machining larger and heavier workpieces with high precision and stability. It offers a wide range of spindle speeds to accommodate various materials and machining requirements. 5 Feet Heavy Duty Lathe Machine may come with various tooling options such as tool holders, chucks, and steady rests

Specifications

|

Length of Bed |

5.5 FEET |

|

Height of Center |

300 MM |

|

Spindle Bore |

80 | 104 | 125 MM |

|

Distance Of Between Centre |

550 MM |

|

Width of Bed |

325 MM |

|

Swing Over Bed |

600 MM |

|

Swing Over Cross Slide |

380 MM |

Advanced Human Machine Interface

This lathe machine incorporates a user-friendly Human Machine Interface, streamlining operation and monitoring. It allows for precise control over the entire machining process, reducing errors and boosting productivity. Operators can quickly adjust settings and oversee the lathe's performance, ensuring optimal output while minimizing downtime.

Energy-Efficient Operation

Designed with lower energy consumption as a core feature, the 5.5 Feet Heavy Duty Lathe Machine helps reduce overall operating costs. Its efficient motor and control system maintain high performance without unnecessary power usage, making it an economical choice for large manufacturing facilities and smaller workshops alike.

FAQ's of 5.5 Feet Heavy Duty Lathe Machine:

Q: How does the Human Machine Interface benefit users of this lathe machine?

A: The Human Machine Interface (HMI) provides an intuitive control panel for easy operation, allowing users to monitor processes, make adjustments, and ensure precision during turning operations. This minimizes errors and enhances productivity.Q: What materials can be processed using this 5.5 Feet Heavy Duty Lathe Machine?

A: This machine is constructed from high-quality metal and is suitable for processing various metals and alloys, making it versatile for a range of industrial applications that require durable and efficient turning capabilities.Q: When is the best time to perform maintenance on the lathe machine?

A: Regular maintenance should be scheduled according to the manufacturer's guidelines, typically after a set number of operational hours or at the end of each production cycle, to maintain optimal performance and extend the machine's lifespan.Q: Where can this lathe machine be installed?

A: The 5.5 Feet Heavy Duty Lathe Machine is suitable for installation in industrial manufacturing plants, workshops, and production facilities where heavy-duty turning and machining tasks are required.Q: What is the process for using this automatic lathe machine?

A: Operators begin by setting up the workpiece, configuring desired parameters through the Human Machine Interface, and initiating the automatic turning process. The machine then handles operations efficiently while minimizing the need for manual intervention.Q: What are the main advantages of lower energy consumption in this lathe machine?

A: Lower energy consumption reduces operating costs and environmental impact. It also makes the machine more sustainable for frequent use in high-volume manufacturing environments, benefiting both efficiency and long-term savings.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry Send SMS

Send SMS English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese