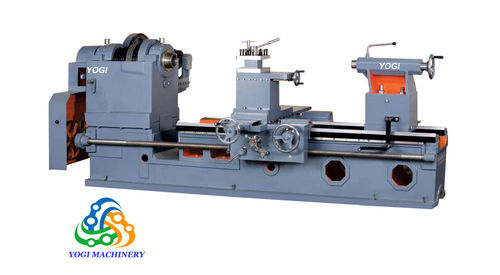

Planer Type Lathe Machine

500000 INR/Unit

Product Details:

- Product Type Planer Type Lathe Machine

- Material Cast Iron, Steel

- Automatic Grade Semi-Automatic

- Control System Manual

- Feature Other

- Color Machine Green (Standard)

- Click to View more

X

Planer Type Lathe Machine Price And Quantity

- 500000 INR/Unit

- 1 Unit

- 4-way

- 4000 mm

- 250 mm

- Up to 0.02 mm

- 2500 mm

- 12650 RPM

- Turning, Facing, Boring, Parting, Drilling

- 500 mm

- 100 mm

- 10 HP Motor

Planer Type Lathe Machine Product Specifications

- Manual

- Planer Type Lathe Machine

- Semi-Automatic

- Other

- Machine Green (Standard)

- Cast Iron, Steel

- 4-way

- 4000 mm

- 250 mm

- Up to 0.02 mm

- 2500 mm

- 12650 RPM

- Turning, Facing, Boring, Parting, Drilling

- 500 mm

- 100 mm

- 10 HP Motor

Planer Type Lathe Machine Trade Information

- Cash Advance (CA), Cash in Advance (CID)

- 5 Unit Per Month

- 1 Months

- Yes

- Sample costs shipping and taxes has to be paid by the buyer

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- All India

Product Description

The Planer Type Lathe Machine is a phenomenal choice for those seeking heavy-duty performance at the lowest price. Highly recommended by industry experts and trending among large-scale manufacturers, this crackerjack machine boasts a robust bed length of 4000 mm and centers height of 500 mm. With triumphant surface finish accuracy up to 0.02 mm, its perfect for turning, facing, boring, parting, and drilling on cast iron and steel. Featuring a sturdy construction, high rigidity, and smooth operation, its conventional manual control and four-way tool post ensure seamless precision. Exported from India, its built for reliability.

Versatile Industrial Applications

Ideal for heavy manufacturing units, workshops, shipyards, and railway factories, the Planer Type Lathe Machine excels on cast iron and steel surfaces. Its exceptional precision and capacity make it suitable for commercial projects requiring robust turning, boring, and drilling applications. Whether used in automotive, aerospace, or infrastructure industries, this lathe ensures top-tier results on demanding surfaces, meeting the highest standards for efficiency and accuracy in industrial processes.

Packaging & Export Specifications

We offer secure packaging for the Planer Type Lathe Machine, ensuring damage-free shipment to international clients. Our main export markets include South America, Middle East, Southeast Asia, and Africa. With stock ready for immediate dispatch, customers receive a prompt quotation upon inquiry. Delivery time is typically 46 weeks, depending on location and order volume, so clients benefit from reliable timelines and complete satisfaction with every order.

Versatile Industrial Applications

Ideal for heavy manufacturing units, workshops, shipyards, and railway factories, the Planer Type Lathe Machine excels on cast iron and steel surfaces. Its exceptional precision and capacity make it suitable for commercial projects requiring robust turning, boring, and drilling applications. Whether used in automotive, aerospace, or infrastructure industries, this lathe ensures top-tier results on demanding surfaces, meeting the highest standards for efficiency and accuracy in industrial processes.

Packaging & Export Specifications

We offer secure packaging for the Planer Type Lathe Machine, ensuring damage-free shipment to international clients. Our main export markets include South America, Middle East, Southeast Asia, and Africa. With stock ready for immediate dispatch, customers receive a prompt quotation upon inquiry. Delivery time is typically 46 weeks, depending on location and order volume, so clients benefit from reliable timelines and complete satisfaction with every order.

| Tailstock Spindle Dia | 80 to 125 mm |

| Centre Height | 15 to 50 Inch |

| Bed Width | 15 to 50 Inch |

| Distance of Between Centres | 1000 to 14000 mm |

| Leading Screw Dia | 45 & 50 mm |

| Leading Screw Pitch | 2 TPI |

| Length of Bed | 9 To 52 Feet |

| Model | YEHDP Series |

| Number of Spindle Speed | 8 no |

| Power Required | 5 to 15 HP |

| Spindle Bore | 125 to 300 mm |

| Spindle Nose | 6 TPI |

| Spindle Speed | 25 to 350 RPM |

| Tailstock Sleeve | MT-5 & MT-6 |

| Country of Origin | Made in India |

FAQs of Planer Type Lathe Machine:

Q: How does the Planer Type Lathe Machine enhance workshop productivity?

A: Its heavy-duty design, high rigidity, and smooth operation allow for efficient machining on tough materials such as cast iron and steel, boosting productivity and reducing downtime in workshops.Q: What commercial operations can the Planer Type Lathe Machine perform?

A: It is suitable for turning, facing, boring, parting, and drilling, making it highly adaptable for industries like automotive manufacturing, railways, and shipyards.Q: Where is the Planer Type Lathe Machine commonly used?

A: This lathe machine is ideal for use in industrial workshops, manufacturing plants, shipyards, and railway maintenance depots where precision heavy-duty machining is essential.Q: What is the process for ordering and packaging the lathe machine?

A: Clients receive a detailed quotation and offer based on requirements. The machine is securely packaged to prevent damage during transit, with stock ready for prompt shipment upon confirmation.Q: What benefit does manual control offer over CNC systems in this lathe?

A: Manual control grants skilled operators direct management over operations, allowing for greater flexibility and customization in machining tasks compared to automated CNC.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese