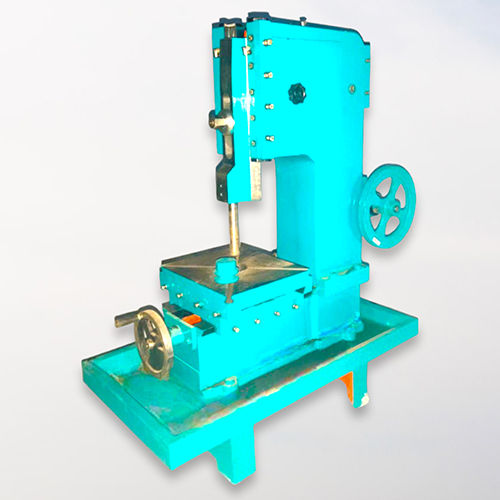

6 Inch 150mm Slotting Machine

Product Details:

- Power Source Electricity

- Operating Type Automatic

- Surface Treatment Painted

- Warranty Yes

- Usage & Applications Industrial

- Click to View more

6 Inch 150mm Slotting Machine Price And Quantity

- 1 Unit

6 Inch 150mm Slotting Machine Product Specifications

- Industrial

- Automatic

- Painted

- Electricity

- Yes

6 Inch 150mm Slotting Machine Trade Information

- Cash in Advance (CID)

- 10 Unit Per Month

- 30 Days

- All India

Product Description

6 Inch 150mm Slotting Machine refers to a machine used for slotting or cutting slots in various materials such as metal, wood, or plastic. The 6-inch measurement typically refers to the maximum stroke or travel length of the machine's ram, which determines the maximum length of the slot that can be cut. In this case, the maximum slot length would be 6 inches or 150mm. Slotting machines are commonly used in machining operations to create slots for keyways, grooves, or other types of recesses. 6 Inch 150mm Slotting Machine typically consists of a vertical ram that moves up and down, carrying a cutting tool or a slotting tool. The workpiece is held on a table or fixture that allows precise positioning.

Specifications

| Adjustable Stroke | 10 TO 150 MM |

| Ram Adjustment | 150 MM |

| Longitudinal Movement | 200 MM |

| Cross Movement | 110 MM |

| Number Of Speed | 3 SPEED |

Efficient Industrial Slotting Solution

Our 6 Inch Slotting Machine is built for high-precision tasks in demanding industrial setups. It automates the slotting process, allowing users to achieve consistent slot cuts with minimal manual intervention. The durable painted finish protects the machinery from corrosion, extending its operational life and maintaining performance.

Designed for Reliability and Ease

This slotting machine integrates advanced automation, making it straightforward to operate even in high-volume manufacturing environments. The use of electricity as its power source avoids the complexity and upkeep issues of other energy options, keeping operations smooth and efficient.

Comprehensive Support and Assurance

As an established exporter, manufacturer, and supplier in India, we provide comprehensive support and warranty coverage for every 6 Inch Slotting Machine. This ensures peace of mind and maximal uptime for our industrial clients, backed by accessible service channels.

FAQ's of 6 Inch 150mm Slotting Machine:

Q: How does the automatic operation of the 6 Inch Slotting Machine benefit industrial users?

A: The fully automatic operation streamlines the slotting process, reducing manual effort and increasing productivity. It allows for precise, repeatable slot cuts, saving time and ensuring consistent results in industrial environments.Q: What materials can be processed with this slotting machine?

A: This machine is primarily designed to cut slots in metals and rigid materials commonly used in industrial applications. It is suitable for steel, iron, aluminum, and similar materials requiring precise slotting.Q: When should regular maintenance be performed on this slotting machine?

A: Regular maintenance intervals depend on the frequency and intensity of use, but it is recommended to inspect and service the machine monthly to ensure optimal performance and longevity. Follow the guidelines in the user manual for best results.Q: Where is this slotting machine manufactured and exported from?

A: The 6 Inch Slotting Machine is manufactured and supplied from India. We serve both domestic and international industrial clients as an exporter and supplier.Q: What is the process for operating the slotting machine?

A: To operate the machine, users secure the workpiece, set the required slot size and position, and activate the machine via its controls. The automatic system handles the cutting operation, completing the slot with precision and minimal manual intervention.Q: What warranty and support are offered with this slotting machine?

A: Every machine is provided with a warranty that covers manufacturing defects and certain operational issues. Support includes spare parts, technical guidance, and after-sales service to ensure your machine remains in top condition.Q: What are the key advantages of having a painted surface treatment on this slotting machine?

A: The painted surface provides resistance to corrosion, enhances durability, and ensures easier cleaning and maintenance. This ensures a longer service life for the machine even in challenging industrial environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry Send SMS

Send SMS English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese