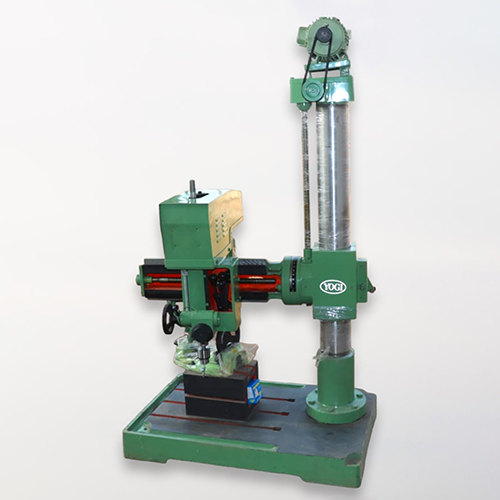

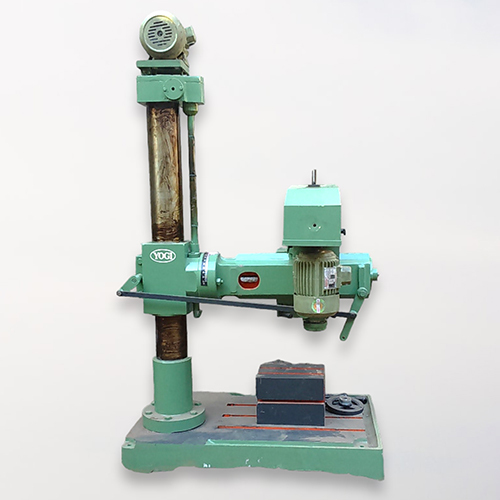

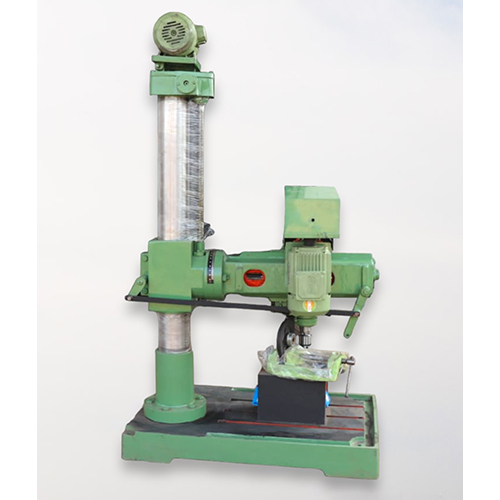

25 MM 1 Inch Radial Drill Machine

Product Details:

- Condition New

- Noise Level 80 dB

- Cutting Area 25 mm diameter max

- Features Smooth operation, high durability, precise drilling, adjustable arm, robust construction

- Motor Power 1 HP

- Diameter 25 mm

- Table Size 300 mm x 300 mm

- Click to View more

25 MM 1 Inch Radial Drill Machine Price And Quantity

- 90000 INR/Unit

- 1 Unit

- MT-3 (Morse Taper-3)

- 175 mm

- 900 mm

- 800 x 500 mm

- 250 mm

- 25 mm

- 130 mm

- 700 mm

- 8

- 250 mm

- Optional

- 28 mm

25 MM 1 Inch Radial Drill Machine Product Specifications

- Standard industrial color

- 25 mm (1 inch) Drilling

- 1 HP

- Smooth operation, high durability, precise drilling, adjustable arm, robust construction

- New

- Automatic

- Radial Drill Machine

- 25 mm diameter max

- 80 dB

- Metal

- 1 HP

- No

- No

- Radial Drill Machine

- 900 mm x 800 mm x 1800 mm

- Metal drilling, manufacturing, workshops, fabrication units

- 90 2100 RPM (variable)

- 300 mm x 300 mm

- Approx. 375 kg

- 50 Hz

- 25 mm

- Electric

- 220-440 V

- MT-3 (Morse Taper-3)

- 175 mm

- 900 mm

- 800 x 500 mm

- 250 mm

- 25 mm

- 130 mm

- 700 mm

- 8

- 250 mm

- Optional

- 28 mm

25 MM 1 Inch Radial Drill Machine Trade Information

- Cash in Advance (CID), Cash Advance (CA)

- 10 Unit Per Month

- 30 Days

- Asia

- All India

Product Description

25 MM 1 Inch Radial Drill Machine refers to a machine used for drilling holes in various materials, such as metal, wood, or plastic. The 25mm measurement indicates the maximum drilling capacity of the machine, meaning it can drill holes up to 25mm in diameter. Additionally, the 1 inch measurement represents the approximate equivalent in inches. They have a radial arm that can rotate around a vertical column and can be positioned at various angles, allowing for flexibility in drilling operations. 25 MM 1 Inch Radial Drill Machine may have adjustable spindle feed rates to control the speed at which the drill descends into the workpiece.

Specifications

|

Model Name/Number |

YRD-25 |

|

Brand |

Yogi |

|

Drilling Capacity in MS |

25 mm |

|

Drilling Capacity in CI |

30 mm |

|

Spindle Speed |

110-2880 RPM |

|

Spindle Travel |

200 mm |

|

Box Table Size |

250 x 205 x 205 mm |

|

Column Diameter |

127 mm |

|

Spindle Nose |

MT-4 |

|

No. of Spindle Speed |

8 |

|

Diameter of Ram |

72 mm |

|

Max. Drilling Radius |

910 |

|

Dist. from Spindle to base |

810/130 (Max/Min) |

|

Dist. from Column to Spindle |

620/350 |

|

Drilling Head Motor |

1 HP |

|

Lifting arm Motor |

0.5 HP |

|

V-BELT Section |

B-40 & B-23 |

|

Machine Measurement |

1020 x 810 x 1830 mm |

|

Approx Weight |

425 Kg |

|

Body Material |

Mild Steel |

Precision Drilling for Industrial Needs

Engineered for metal drilling, the 25 MM Radial Drill Machine boasts consistent performance with an MT-3 spindle taper, variable speeds, and a generous worktable. Durable construction meets strict industrial standards, ensuring reliable use in demanding environments such as workshops and manufacturing units.

Versatile and Adjustable Operation

With its 700 mm arm length, 250 mm arm lift, and adjustable spindle distance, this machine accommodates various drilling requirements. Suitable for large or irregular workpieces, the design ensures versatility without compromising on stability or drilling precision.

Smooth Performance and Easy Maintenance

Powered by a 1 HP electric motor, the drill maintains smooth operation while keeping noise levels below 80 dB. Its robust build minimizes vibration, while the user-friendly controls make it easy to adjust speeds and arm positions. Optional coolant pump and automatic features allow for seamless operation and longer machine life.

FAQ's of 25 MM 1 Inch Radial Drill Machine:

Q: How does the 25 MM Radial Drill Machine ensure precise drilling?

A: The machine features an MT-3 spindle taper, adjustable arm, and variable speeds ranging from 90 to 2100 RPM, providing precise control over drilling operations. Its robust construction reduces vibrations, and a maximum spindle travel of 175 mm allows for accurate depth control on various materials.Q: What materials and applications is this radial drill machine suitable for?

A: The drill is designed for metalworking and is ideal for drilling into steel (up to 25 mm) and cast iron (up to 28 mm). It is commonly used in manufacturing plants, fabrication workshops, and general engineering applications where accurate, repeatable penetration is required.Q: Where can the 25 MM Radial Drill Machine be installed and used?

A: This machine is suitable for installation in industrial and commercial settings, including metalworking shops, production facilities, and educational workshops. Its manageable dimensions and weight (approx. 375 kg) allow for flexible placement within standard workshop floor plans.Q: What is the process for adjusting the arm and table positioning?

A: The machine's arm and worktable can be smoothly adjusted through simple manual controls, allowing the operator to change height, arm extension (up to 700 mm), and table travel (250 mm) as required. This flexibility enables easy accommodation of different workpiece sizes and drilling angles.Q: When should a coolant pump be used with this radial drill machine?

A: A coolant pump, offered as an optional accessory, is recommended during extended drilling sessions or when working with harder metals to prevent overheating. Using coolant improves tool life and maintains drilling accuracy by efficiently managing heat generated during operation.Q: What are the key benefits of using this radial drill machine for metal fabrication?

A: Major benefits include precise and efficient drilling, robust build for high durability, user-friendly controls, and adaptability to a wide range of workpiece sizes. Its smooth operation and quiet performance contribute to safer and more productive working environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese