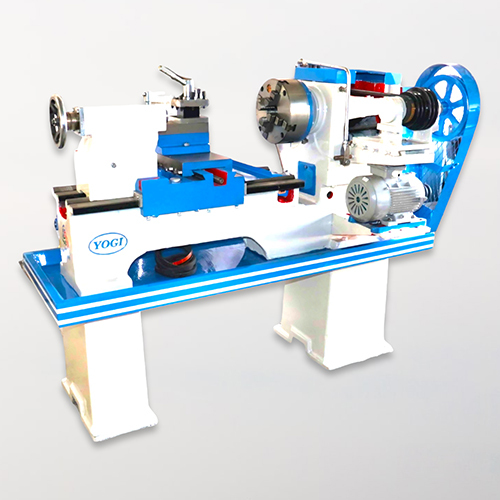

5.3 Feet Medium Duty Lathe Machine

Product Details:

- Material Metal

- Automatic Grade Automatic

- Control System Human Machine Interface

- Feature Lower Energy Consumption

- Warranty Yes

- Click to View more

X

5.3 Feet Medium Duty Lathe Machine Price And Quantity

- 1 Unit

5.3 Feet Medium Duty Lathe Machine Product Specifications

- Lower Energy Consumption

- Automatic

- Human Machine Interface

- Yes

- Metal

5.3 Feet Medium Duty Lathe Machine Trade Information

- Cash in Advance (CID)

- 10 Unit Per Month

- 30 Days

- All India

Product Description

Specifications

| Model | YMD D5 | YMD A5 |

| Length of Bed | 5.3 FEET | 5.3 FEET |

| Height of Centre | 250 MM | 215 MM |

| Spindle Bore | 80 MM | 50 MM |

| Distance Of Between Centre | 725 MM | 725 MM |

| Width of Bed | 279 MM | 279 MM |

| Swing Over Bed | 450 MM | 400 MM |

| Swing Over Cross Slide | 250 MM | 225 MM |

| Swing in Gab | 750 MM | 650 MM |

Robust Engineering and Versatility

Built from high-grade metal, the 5.3 Feet Medium Duty Lathe Machine offers excellent durability and stability for diverse machining needs. Its moderate size fits most workshop environments, offering versatility without compromising on performance or precision. Designed for both novice and experienced operators, this lathe brings reliability and ease-of-use together.

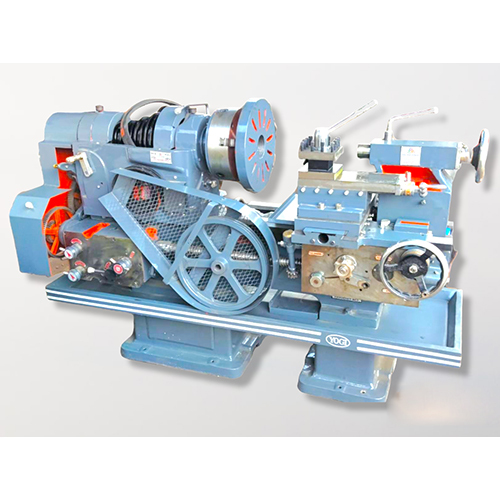

Advanced Automation and Control

Equipped with an intuitive Human Machine Interface, this lathe simplifies complex operations through automated controls. The automatic grade feature reduces manual intervention, streamlining workflow and saving operator time. The result is improved accuracy and repeatability, which is crucial for delivering consistent results in industrial settings.

FAQ's of 5.3 Feet Medium Duty Lathe Machine:

Q: How does the Human Machine Interface improve machine operation?

A: The Human Machine Interface (HMI) provides a user-friendly platform for monitoring and controlling the lathe. It allows operators to easily adjust settings and automate processes, reducing manual errors and increasing efficiency during operation.Q: What are the primary uses of the 5.3 Feet Medium Duty Lathe Machine?

A: This lathe is primarily used for turning, facing, drilling, and shaping metal workpieces. Its medium size and automated controls make it suitable for small-to-mid-sized fabrication shops seeking reliable machining with consistent quality.Q: When should I consider using this automatic lathe over manual options?

A: Switch to this automatic lathe when you require higher productivity, reduced labor dependency, and more precise control over repetitive tasks. Its automation and efficiency lead to significant time and cost savings, especially for batch production operations.Q: Where is this lathe machine best installed for optimal performance?

A: The machine is best installed in well-ventilated industrial workshops or fabrication units with adequate space, solid flooring, and stable power supply for safe and efficient operation. It is designed to suit both new and established workshops across India.Q: What is the process for warranty support if issues arise?

A: The machine comes with a warranty. If you encounter any operational issues, you may contact the supplier or manufacturer directly. They will guide you through the support process, including troubleshooting, repairs, or part replacements as per the warranty terms.Q: How does lower energy consumption benefit users?

A: Lower energy consumption reduces operational costs and contributes to a more sustainable workshop environment. This feature allows users to maintain productivity while saving on energy bills, making it an economical choice for ongoing operations.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese